Low nitrogen condensing vacuum hot water boiler

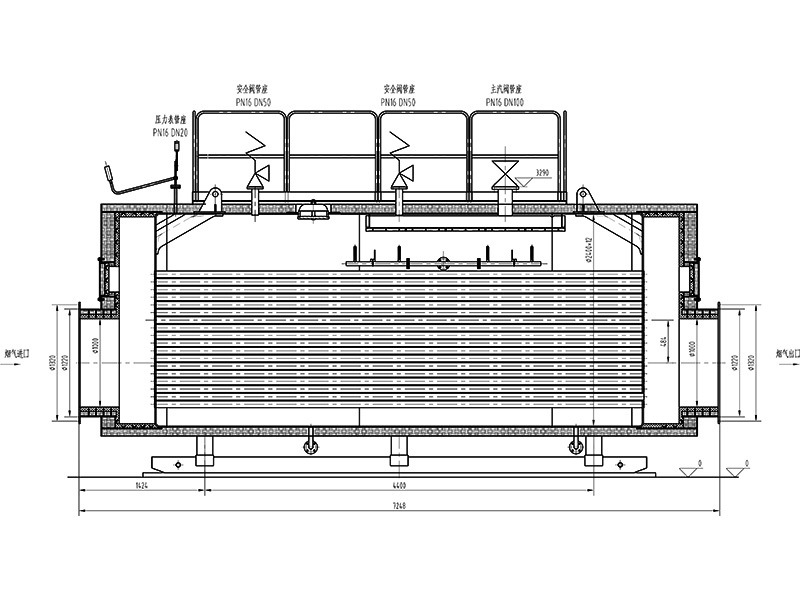

The boiler adopts a three-pass structure, and the smoke tube adopts a threaded smoke tube to enhance heat transfer.The unique wet-back back-combustion chamber structure eliminates traditional refractory and thermal insulation materials,reduces the temperature of the smoke chamber of the unit, and the double-layer mirror aluminum foil aluminum silicate heat preservation of the whole unit reduces the heat loss of the unit to the limit.A waste heat recovery device is installed at the tail to reduce the temperature of the flue gas, realize the release of the sensible heat of the flue gas and the latent heat in the water vapor, and further improve the efficiency of the boiler.

Category:

0.35-14MW ZWNS series boiler

Product description

Advantages of low nitrogen condensation technology

High efficient

The boiler adopts a three-pass structure, and the smoke tube adopts a threaded smoke tube to enhance heat transfer.The unique wet-back back-combustion chamber structure eliminates traditional refractory and thermal insulation materials,reduces the temperature of the smoke chamber of the unit, and the double-layer mirror aluminum foil aluminum silicate heat preservation of the whole unit reduces the heat loss of the unit to the limit.A waste heat recovery device is installed at the tail to reduce the temperature of the flue gas, realize the release of the sensible heat of the flue gas and the latent heat in the water vapor, and further improve the efficiency of the boiler.

Durable

Due to inside the boiler is airtight overall atmosphere, and at runtime,medium water oxygen precipitation among them, from outside,long-term oxygen corrosion will not occur in the furnace,one-time add a small amount of heat medium water,small amount of calcium and magnesium ions, limited the runtime does not increase and no reduce, So there is no scaling inside the boiler,Increased the boiler service life, is the general boiler service life 1.5~2 times.Part of the heat exchanger is made of stainless steel tube,corrosion resistance, design service life is more than 20 years.

Multi-usage

One unit can be equipped with multiple heat exchangers to supply hot water at different temperatures and for different purposes,such as central air-conditioning water,sanitary hot water,process hot water,etc. The company follows the principle of "maximum energy allocation" to ensure that each heat exchanger 'can 'achieve the maximum amount of heating when heating individually,so that users can obtain the best results with the minimum investment.

Security

As the pressure of the medium circulation system of the vacuum hot water unit is lower than the atmospheric pressure,the internal absolute pressure of the unit during operation is 0.02 ~0.065mpa,and the unit is in the vacuum state, so there will be no explosion.

Low Nitrogen

The boiler is designed with a large furnace with large combustion space and is equipped with imported low-nitrogen burners.Nitrogen oxide emissions can be as low as 30mg/m3.

Convenient

This series of boilers have compact structure,easy to install and transport,symmetrical movable hinge front and rear smoke doors, easy to open, easy to overhaul and clean.The rear smoke box is provided with two doors and the lower part is provided with fire observation holes and inspectors for convenience of inspection. The solid base can install the boiler on the base,and there is a ladder for convenient installation of other auxiliary equipment.

Accurate control

The PLC programming controller automatically adjusts operation according to load changes. The hot water temperature can be set freely between 20 and 90 ℃, and the temperature can be automatically adjusted to ensure constant temperature.The controller automatically detects the faults in the burner and the furnace body and sends out an audible and visual alarm. It controls the burning time and automatically adjusts the entire combustion process of the first and second stages to maintain normal operation,reduce the number of starts and stops caused by load changes,and reduce the loss of on-off purge heat.

Investment savings

1. The heat excharger of the vacum hot water boier is built-in,which saves a lot of auxiliary ecquipment investment and auxillary equipment installation costs (saves a circulaticn pump.pate heat exchanger, and corresponding ppelne valves, etc., and reduces electical control system loops) thereby saving investment.

2. The auxiliary equipment is reduced and the floor space is reduced. The vacum hot water boier room can save 30%-50% of the floor space compared with the traditional boiler room, saving investment.

3. The vacuum hot water boiler has a small volume, which is conducive to large-tonnage modularization .The load time difference can be used to reduce the total load tonnage, which is convenient for capacity expansion and saves initial investment.

4. No need to go through registration,reducing registration fees.Installation and use procedures are very simple, no boiler inspecion and boiler inspection, no annual inspection. No need to be equipped with a licensed boiler worker.

5.lt is not easy to scale, no oxygen corrosion, and has a long service life, reaching more than 20 years, which is twice the service life of ordinay boilers.

6. Advanced control and fully automatic operation. One machine has multiple functions and flexible selecton. The built-in stainess steel heat exchanger ensures water quality and can directly supply sanitary domestic hot water.

Technical characteristics and parameter table of Fully premixed low nitrogen condensing copper tube hot water module boiler

| Project/TYpe | Z1-WNS*-1.25/70/50-Y(Q) | ||||||||||

| 0.7 | 1.4 | 2.1 | 2.8 | 4.2 | 5.6 | 7.0 | 10.5 | 14 | |||

| Rated thermal power | MW | 0.7 | 1.4 | 2.1 | 2.8 | 4.2 | 5.6 | 7.0 | 10.5 | 14 | |

| Supply/retum water temperature | ℃ | 70/50 | 70/50 | 70/50 | 70/50 | 70/50 | 70/50 | 70/50 | 70/50 | 70/50 | |

| pressure of heat exchanger | MPa | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Thermal efficiency | % | 96.5 | 96.2 | 96.3 | 96.1 | 96.3 | 96.4 | 96.7 | 96.5 | 96.3 | |

| Fuel Consume | Light oil | Kg/h | 61.4 | 125.9 | 184.7 | 251.9 | 370 | 493.3 | 616.7 | 924.9 | 1233.3 |

| Natural gas | Nm³/h | 72.1 | 144.2 | 216.8 | 288.6 | 432.1 | 576.5 | 720.4 | 1080.1 | 1440.3 | |

| Heat exchange area of exchanger | ㎡ | 13.7 | 30.8 | 39.8 | 53.6 | 75.1 | 100.2 | 126.7 | 190.1 | 253.4 | |

| Boiler heating area | ㎡ | 26.6 | 54.88 | 70.5 | 87.9 | 133.1 | 177.6 | 221.8 | 332.7 | 433.6 | |

| Condenser | ㎡ | 25.2 | 48.7 | 60 | 78 | 117 | 156 | 186 | 269 | 338 | |

| Power consumption | KW | 3 | 6.5 | 8 | 11 | 17 | 24 | 26 | 42 | 50 | |

| Boiler water capacity | m³ | 1.8 | 2.4 | 4.8 | 5.3 | 7.6 | 9.5 | 12.8 | 16.8 | 20.2 | |

| Boiler weight | t | 5.1 | 7.9 | 9.3 | 10.7 | 14.1 | 18.6 | 23.8 | 32.2 | 41.5 | |

| Hearth size | Diameter | mm | 700 | 800 | 900 | 1000 | 1100 | 1300 | 1400 | 1600 | 1800 |

| Length | mm | 1540 | 2500 | 2800 | 3200 | 3800 | 4500 | 5108 | 5460 | 6000 | |

| Boiler back pressure | Pa | 623 | 643 | 1053 | 1280 | 1447 | 1510 | 1648 | 2118 | 2580 | |

| Inlet pipe | mm | 100 | 125 | 150 | 150 | 200 | 200 | 250 | 300 | 300 | |

| Safety valve tube | mm | 100 | 100 | 100 | 100 | 150 | 150 | 150 | 200 | 200 | |

| Sewage pipe | mm | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Chimney diameter | mm | 300 | 350 | 400 | 400 | 600 | 800 | 800 | 900 | 1000 | |

| Shape Size | Long | mm | 3920 | 4350 | 5060 | 5510 | 6000 | 6680 | 7180 | 7760 | 8120 |

| mm | 1763 | 1920 | 2063 | 2160 | 2360 | 2560 | 2720 | 2870 | 2960 | ||

| Hight | mm | 2620 | 2910 | 3270 | 3310 | 3490 | 3490 | 3950 | 4133 | 4460 | |

| Base size | Long | mm | 3700 | 4350 | 4840 | 5290 | 5770 | 6260 | 6850 | 7230 | 7750 |

| mm | 1600 | 1750 | 1900 | 2000 | 2200 | 2400 | 2550 | 2700 | 2800 | ||

Product Message

Get in touch with our team in a timely manner and be happy You offer help

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Us

Address: Wuzhi county zhan shop new district northwest corner Changwu road and hongyuan road intersection,Jiaozuo City, Henan Province,China

Sales Hotline: +86-371-63663000

Service Hotline: +86-371-63663000

ADD:Yiyang Industry Gathering Zone,Luoyang City, China